Warning: The following contains full spoilers for the Forged In Fire Season 9 episode “Gladiators of the Forge: Vikings vs. Gladiators”, which aired on July 21 on History.

(Image credit: The History Channel)

Forged In Fire’s current tournament-style competition “Gladiators of the Forge” continued this week with two more rounds of bladesmithing action. The latest episode brought much of the familiar artistry we’ve come to love along with some actionable tips fitting for veteran and aspiring bladesmiths alike. After Action Review is our opportunity to not only enjoy shows like Forged In Fire, but to walk away with valuable insights making each of us better at our craft. Let’s review.

WHAT WAS SUPPOSED TO HAPPEN?

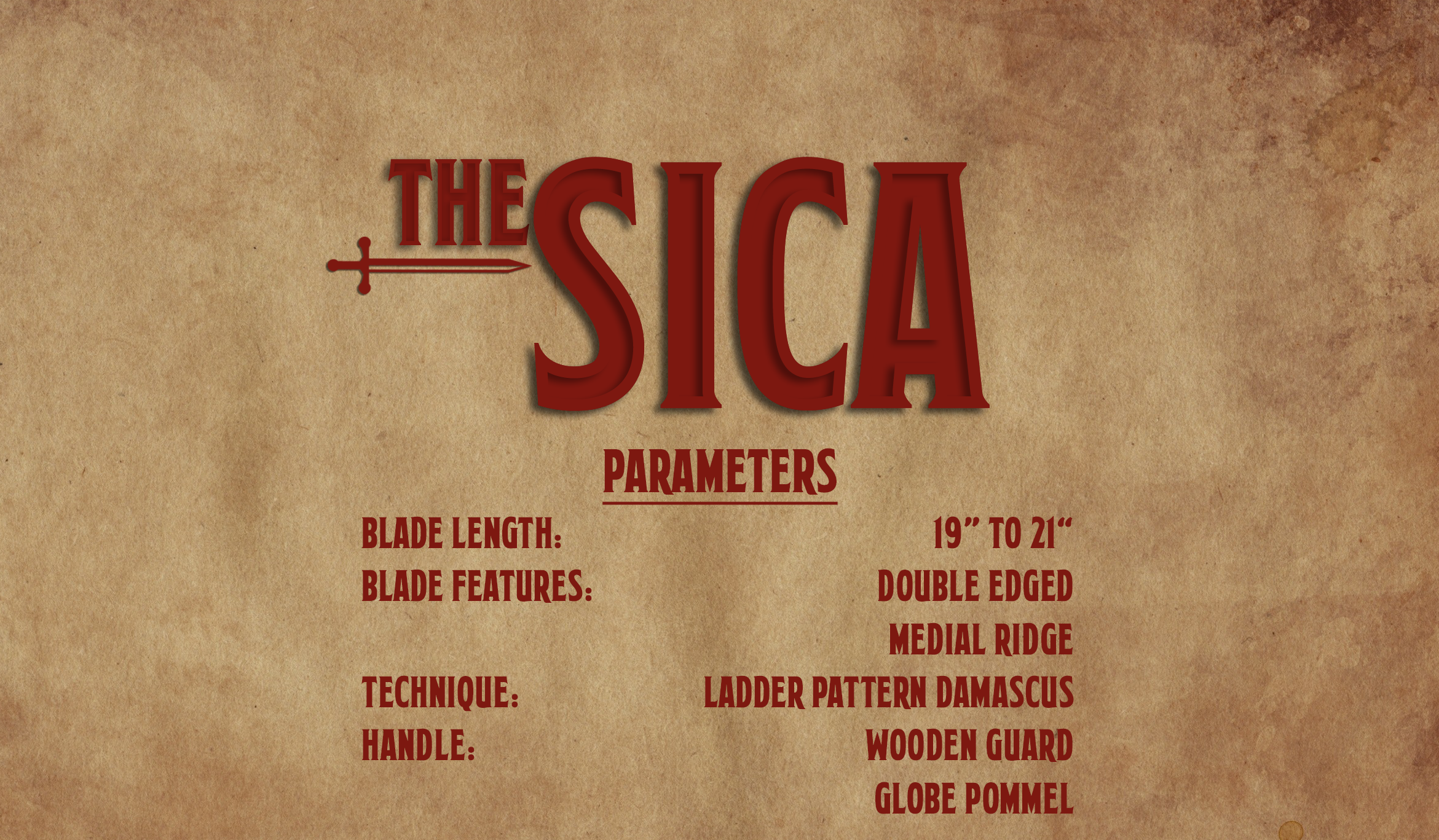

- Round one saw the return of Jessie, the two-time champion from last week’s episode. Jessie won the coin toss and, electing to choose the weapon, selected the Sica sword. Parameters for this weapon included a double-edged blade with a length of 19” to 21”, a medial ridge, a fuller on both sides of the blade, and a pommel. Our challenger, Eric, was left to select the forge welding technique. Hoping to create an advantage against the proven Jessie, Eric selected ladder pattern damasucs with a minimum layer count of 120.

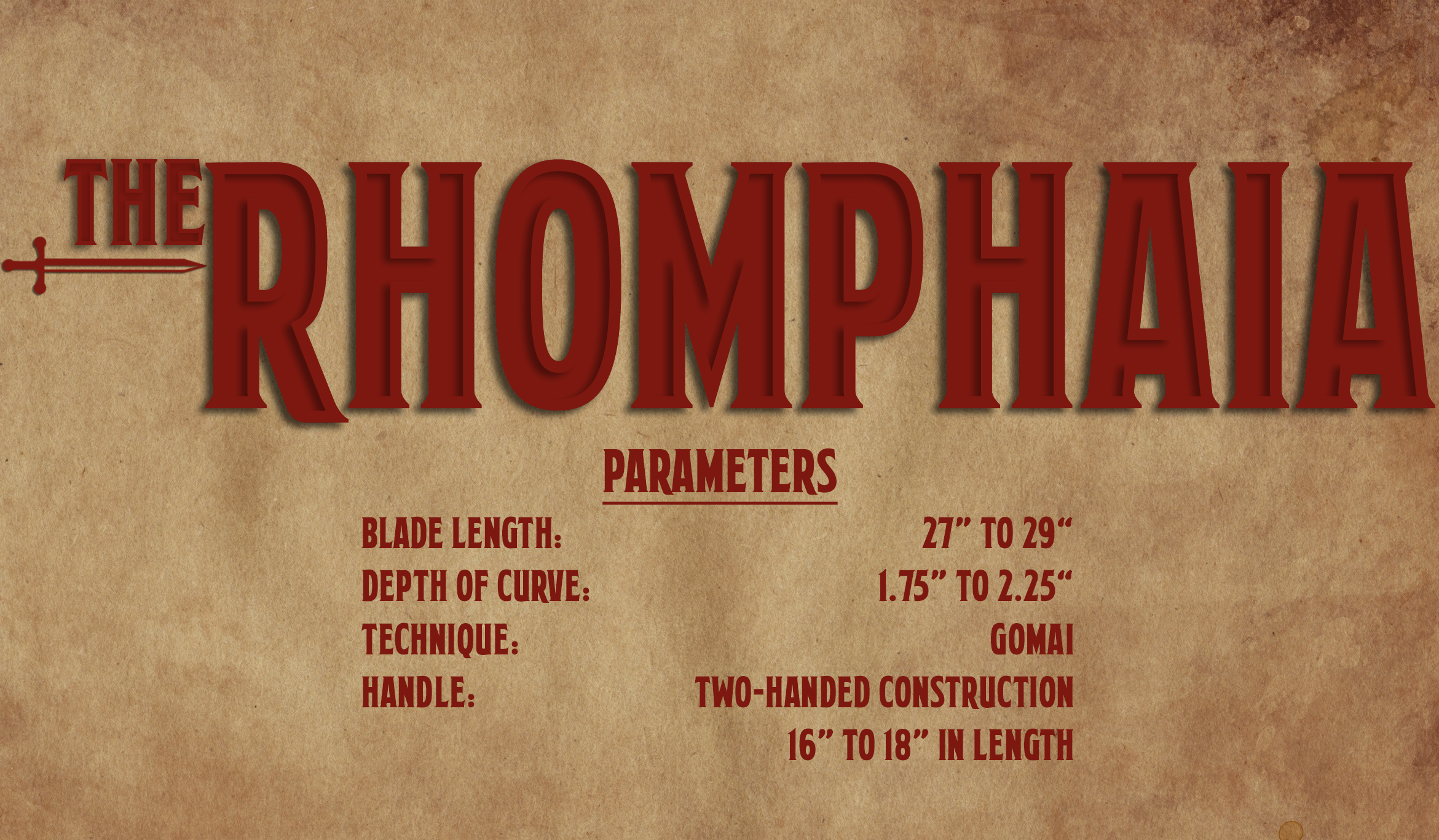

- Round two saw the winner of our first battle return to the forge (SPOILER INCOMING- You’ve been warned) to take on a new challenger. Following an intense round, Jessie proved too much for Eric and earned his third straight victory. Unphased, Jason entered poised to challenge the newfound veteran. Jason correctly chose tails, and selected the notorious Rhomphaia. Parameters for this long, curved sword include a single-edged blade length of 27″ to 29″ with a curve depth of 1.75″ to 2.25″ and a 16″ to 18″ handle. Jessie was tasked with selecting the forging method and, wanting a break from damascus, chose Gomai.

WHAT ACTUALLY HAPPENED?

ROUND ONE

- MATERIAL: While both smiths chose the same material for crafting their Sica (1095 and 15n20), they did differ in the amount used. Jessie started with 12 layers each (24 total), while Eric went with 7 layers (14 total).

- TECHNIQUE: With differing amounts of starting material, the smiths took differing paths to those 120 layers. Jessie forged out his original 24 layers, cutting his original billet into 5 even pieces. He then stacked and forge welded the pieces into a final billet of 120 layers.

Eric, having less material to start, chose to draw out and cut his original billet into 3 pieces, giving him 42 layers. He then repeated that process, giving him 126 layers. - HEAT TREAT: Both smiths were successful in their first attempt at heat treating their blade.

- GRIND: During the forging process, Eric ground clean both sides of the pieces of his billet before stacking. This loss of material coupled with the low number of starting layers forced Eric to gain additional length by tapering his blade. Additionally, Eric’s attempts to put a sharp edge on his blade were limited due to a lack of time for “fit and finish”.

- HANDLE: While constructing his handle, Jessie struggled to gain a mechanical connection for his pommel. His early attempts at drilling a pin through the round pommel failed, leaving him to rely on a built up layer of weld on the end of the tang.

Eric also had initial struggles assembling his wooden handle, with his attempt at a drill through construction resulting in a total split of material. Luckily, the material split evenly down the middle and was able to be firmly secured to the tang using a pin. - STRENGTH TEST: For the strength test, both blades were subject to the chariot wheel chop. Jessie’s blade survived the test with no damage or deformations. It was noted that his handle was “ugly”, and his pattern was visible, though not vibrant.

Eric’s blade also survived, though with some minor glinting. His handle had a few “hot spots”, but did not injur the user. - SHARPNESS TEST: To gauge sharpness, the blades were put through the tube slice. Jessie’s blade had nice balance and cleanly cut through all the tubes.

Eric’s blade also had nice balance, but suffered when it came to cutting the tubes. The lack of a defined edge coupled with the glinting picked up during the strength test resulted in a dull blade. - RESULTS: Ultimately, Eric’s lack of a sharp edge did him in. Jessie emerged victorious, claiming his third consecutive victory in the forge.

ROUND TWO

- MATERIAL: By definition, a Gomai blade is composed of 5 layers of forge welded material. To achieve this, Jason selected a 1095 core flanked by 15n20 with a mild steel outside. Jessie decided to mix it up, going with an 80crv2 core surrounded by 15n20 and mild steel edges.

- TECHNIQUE: Considering the length of this weapon, the smiths were given 12″ pieces of material. While the overall Gomai construction is the same for both smiths, they did differ in their approach to the intial forge weld. Jason cut those 12″ pieces in half, stacking the two pieces of like material to create a homogenous layer. Ultimately, this gave Jason a shorter, but thicker billet than his competitor (Jessie’s billet consisted of 5 long, thin layers).

To achieve the trademark curve of the blade, the smiths beat them over the horn of their anvils. Jessie was able to get a consistent curve spanning the entire length of the blade, while Jason’s curve was more drastic and towards the tip. - HEAT TREAT: Long, thin blades tend to have issues with the heat treat, and these two were no exception. Both smiths had warping issues after pulling their blades out of the quench.

Upon cooling, Jessie’s blade developed a significant crack that traversed the length of the spine. Though not ideal (or pretty), Jessie was able to repair the crack using MIG weld. - GRIND: With significant warps, both smiths made attempts to grind their blades straight. Neither was very successful, and they both used heat and pressure to straighten them even further.

- HANDLE: The traditional Rhomphaia has a one-piece wooden handle construction. Both smiths used cedar scales to finish their handles, a material that is not ideal for handles.

- KILL TEST: The first test was the kill test; the pig slice. Jason’s blade survived, deeply cutting the carcas, but taking a bend towards the tip in the process. Jessie’s blade cut the pig in two while taking no damage. Also, Jessie’s handle was comfortable.

- DYNAMIC STRENGTH TEST: To test the strength and sharpness of the blades, they were put through a skull chop and foam tube slice. While Jason’s blade did survive the test, it was noted that the curved blade was more like a “bend”, and the handle construction did not match the example weapon. Jessie’s blade passed with flying colors, with a construction and profile accurate to the example.

- RESULTS: Despite his blade not being the prettiest he’s made in the competition, Jessie took home the crown for the fourth time. Even though they tested equally, Jason’s blade differed too much from the example weapon to knock of the reigning champion.

WHAT WENT WELL?

- Both round one smiths were able to produce servicable weapons. The drastic profile of the Sica sword did not trip them up, and they were able to effectively heat treat their weapons. Also, they were both able to successfully craft their handles despite experiencing potentially catastrophic issues.

- The round two smiths were able to overcome the adversity that comes with forging such a large blade. They maintained their composure as they delt with warping issues and produced servicable weapons. Additionally, Jessie didn’t give up when his blade cracked, finding a repair that worked.

WHAT DIDN’T GO WELL?

- In round one, Eric’s initial decision to use less material seemed like a good choice, but quickly proved problematic. The material lost during the forging process forced him to fight to meet the minimum length parameters.

- Also in round one, Eric’s early decision to use an additional cut and stack to achieve the requisite layer count ate up valuable time. That lack of time bit him in the end, preventing him from being able to put a satisfactory edge on the blade.

- In round two, Jason’s technique for curving his blade was faulty. While the idea of using the anvil horn is correct, his placement of the blade while striking the horn produced a signicant bend rather than a consistent curve, a mistake he recognized but failed to correct.

- Additionally, Jason failed to pay close attention to the shape of the handle on the example weapon. He chose to create a handle shape that was inconsistent and not needed.

WHAT DID WE LEARN?

- Plan smart! Early decisions in the forging process can have drastic ramifications on your ability to finish your blade.

- Start with more than enough material! You can always cut off material if you find you have excess. Adding material, while possible, requires additional time and may lead to blade failures.

- Pay attention to the details! Forging any weapon is difficult, especially when under a time crunch. Choosing not to correct identified issues may save time, but also may prove fatal in the competition. When all else is equal, the weapon that is closest to the example will come out on top.

What did you think of this episode? Did we miss a major lesson or takeaway? Let us know in the comments below.

New episodes of Forged in Fire air Wednesday nights at 9/8c on History.

‘After Action Review’ is an ongoing series from Brute de Forge in which we dissect popular bladesmithing content, giving you actionable lessons you can apply to your craft today.